How CCUS can help to attain net zero carbon emission

CCUS can help to attain net zero carbon emission | Source: https://spectra.mhi.com/

Carbon Capture, Utilization and Storage (CCUS) is a set of evolving technologies that capture carbon dioxide (CO2) emissions at their source, preventing them from entering the atmosphere. At the same time, it can also work fairly well by absorbing CO2 emissions directly from the air. There are various methods to achieve carbon capture like capture, sequestration, utilization, mobile carbon capture, direct air capture, oxy-combustion, or natural process like nature itself.

Carbon capture methodologies

The capture method, as the name suggests, captures CO2 from the exhaust and treated it adequately, and finally stored it. Sequestration is the process of depositing the captured CO2 in geological formations. Utilization is the direct use of captured CO2 (for example in cement) or the conversion of captured CO2 and other gases into useful industrial products, such as chemicals or fuels. Mobile Carbon Capture technology can capture CO2 from mobile sources and store it on board, ready to be taken away for sequestration or utilization. Direct Air Capture is the process of capturing CO2 directly from the atmosphere (rather than at the source) and remove CO2 to be sequestered or utilized. Oxy-combustion is a technology that uses pure oxygen to combust fuels, increasing combustion efficiency and increasing the concentration of CO2 in flue gases, enabling easier CO2 capture. Another reliable nature solution is nature itself. Nature can act as a natural carbon sink, such as mangrove trees which sequester carbon far more effectively (up to 100 times faster) and more permanently than terrestrial forests

Plastic waste into hydrogen and high-value carbons: Study finds

Some leading breakthrough

According to the Global CCS Institute’s 2019 Status Report, 40 million metric tons of CO₂ from plants currently in operation or construction are captured and stored each year. Globally, in 2019, there were 51 large-scale CCS facilities in operation or under construction. The Global CCS Status Report shows that global capture and storage capacity has increased by 33% since 2019, and there are 65 commercial CCS facilities in various stages of development globally.

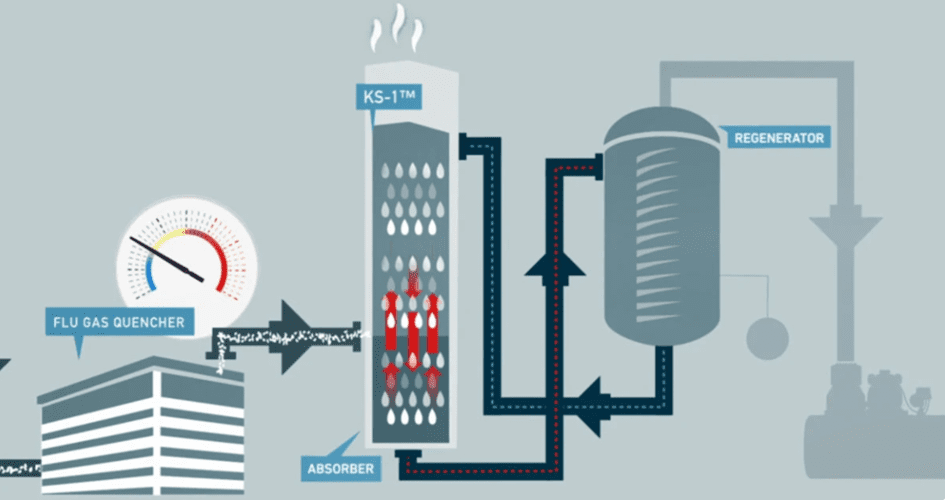

Among the leading service providers, Mitsubishi Heavy Industries Engineering(MHIENG)” Group offers a “Large-scale,” “High-performance” Plant for CO2 Recovery from Flue Gas. It is a commercially available CO2 recovery process KM CDR Process (KANSAI MITSUBISHI Carbon Dioxide Recovery Process) which promises enhanced economic performance for plants of wide-ranging capacities. The MHIENG CO2 recovery process utilizes “KS-1,” an advanced hindered amine solvent, in conjunction with a line of special proprietary equipment. The technology was developed through cooperation between MHIENG and Kansai Electric Power Company, Inc. (KANSAI). The process is based on advanced and proven technology for recovering CO2 from various sources of flue gas. Users who adopt this economical process will enjoy benefits such as low energy consumption, low solvent degradation, and reduced corrosion within the equipment

Also read: Earth may temporarily pass dangerous 1.5℃ warming limit by 2024, major new report says

Observer Voice is the one stop site for National, International news, Sports, Editor’s Choice, Art/culture contents, Quotes and much more. We also cover historical contents. Historical contents includes World History, Indian History, and what happened today. The website also covers Entertainment across the India and World.