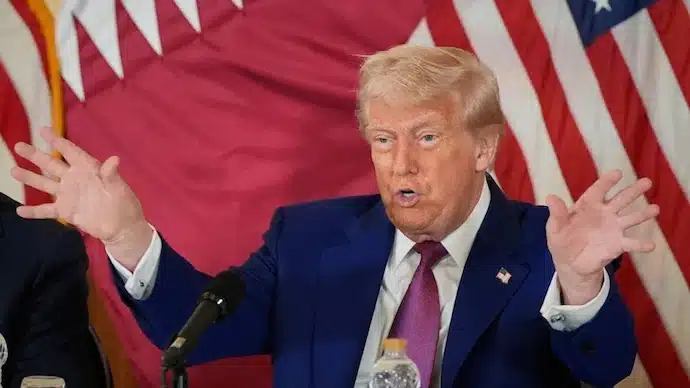

US Manufacturing Struggles Despite Policy Support, Says Donald

US manufacturing is facing ongoing challenges, with recent data indicating a troubling stagnation in the sector. Despite efforts from both the Trump and Biden administrations to bolster domestic production through tariffs and subsidies, job losses and declining output suggest that the industry is struggling to regain its footing. The latest reports reveal that factories cut 7,000 jobs in June, marking the second consecutive month of employment declines, and raising concerns about the future of manufacturing in the United States.

Job Losses and Declining Production

The Labor Department’s recent report highlights a concerning trend in US manufacturing, with employment figures showing a decrease for the second month in a row. In June, factories eliminated 7,000 jobs, contributing to a broader pattern of job losses that could extend into a third consecutive year. The Institute for Supply Management (ISM) also reported that manufacturing activity has contracted in 30 of the last 32 months, indicating a prolonged period of stagnation. Eric Hagopian, CEO of Pilot Precision Products, described the last three years as a “real slog” for the sector, noting that while the situation is not as dire as during the 2008 financial crisis, the industry remains in a stagnant state.

Several factors are contributing to this slowdown, including inflationary pressures that surged following the post-COVID recovery and the Federal Reserve’s aggressive interest rate hikes in 2022 and 2023. Although the Biden administration’s clean energy and semiconductor subsidies initially spurred factory construction, investment levels have since declined, particularly after the return of Trump and the reversal of many green energy incentives.

Impact of Tariffs and Protectionist Policies

Former President Donald Trump’s administration implemented significant tariffs aimed at protecting domestic manufacturing. These tariffs include a 50% levy on steel and aluminum, a 25% tariff on automobiles and parts, and a 10% duty on various other imports. While these measures have provided some companies with a competitive edge, they have also increased costs for US producers reliant on imported materials. Chris Zuzick, Vice President at Waukesha Metal Products, acknowledged that while tariffs can help maintain competitiveness in certain bids, the overall impact on steel prices has been substantial. As of late June, steel prices in the US reached $960 per metric ton, more than double the global average of $440.

Despite the high tariffs, some manufacturers, including Pilot Precision, continue to source steel from countries like France and Austria, citing better price and quality dynamics. The uncertainty surrounding tariff policies has further complicated the landscape for manufacturers. Trump has frequently altered tariff schedules, leaving many in the industry hesitant to make long-term commitments. An ISM survey respondent noted that the current climate is too volatile for firms to solidify their plans.

Reversion to Pre-Pandemic Norms

The recent downturn in manufacturing may also reflect a return to pre-pandemic employment levels. Following the loss of nearly 1.4 million jobs in early 2020, the sector experienced a brief surge during the COVID-19 pandemic, adding 379,000 jobs in 2021 and 357,000 in 2022. However, hiring has plateaued in 2023, and recent data indicates a reversal of this trend. As of June, factory payrolls stood at approximately 12.75 million, nearly unchanged from the 12.74 million recorded in February 2020.

Jared Bernstein, chair of Biden’s Council of Economic Advisers, remarked on the long and complex journey back to pre-pandemic employment levels. Many manufacturers are now waiting for clearer signals from the Trump administration regarding future policies, particularly with the anticipated “One Big Beautiful Bill.” While some industry leaders express hope that targeted tax breaks could provide relief, others caution that it is premature to assess the full impact of tariffs on manufacturing.

Manufacturers’ Cautious Outlook

With ongoing policy fluctuations, rising costs, and weak demand, many manufacturers are adopting a cautious approach to hiring and investment. Chris Zuzick emphasized that the industry is in a state of waiting, as firms seek to navigate the uncertainties of the current economic environment. The combination of tariff unpredictability and cost pressures has left many manufacturers hesitant to commit to new projects or expand their workforce.

As the manufacturing sector grapples with these challenges, the outlook remains uncertain. Industry leaders like Hagopian and Zuzick are hopeful for a more stable environment that could foster growth, but for now, many factories are holding off on hiring and investment plans. The path forward for US manufacturing will depend on clearer policy direction and a resolution to the current economic pressures facing the industry.

Observer Voice is the one stop site for National, International news, Sports, Editor’s Choice, Art/culture contents, Quotes and much more. We also cover historical contents. Historical contents includes World History, Indian History, and what happened today. The website also covers Entertainment across the India and World.

Follow Us on Twitter, Instagram, Facebook, & LinkedIn