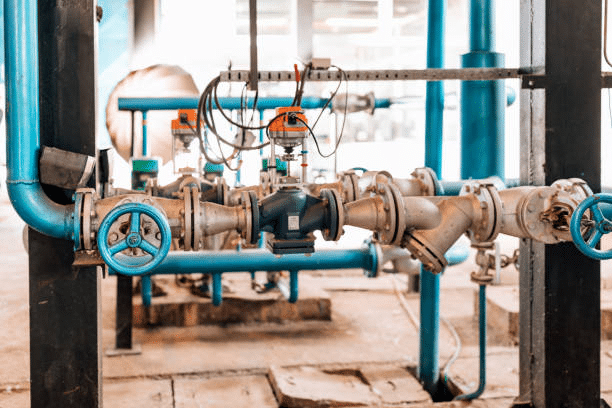

How a Stainless Steel Electric Flat Gate Valve Works In Much Corrosive Regions

In the case of regions that deal with harsh aggressive fluids and even chemicals, there is absolutely no doubt that reliable and durable valves did a great job in those needs. A solution that does effortlessly stand out of the rest in such environments is the stainless steel electric flat gate valve. These valves are tailored for optimal sealing, control capabilities, and withstand needless operational conditions. This article examines actuated gate valves, the significance focusing on high corrosion environments and the electric flat gate valve’s relevance to how fluid control, safety and operational efficiency is influenced.

What is a Stainless Steel Electric Flat Gate Valve?

A stainless steel electric flat gate valve is one of a kind as it is the first model to incorporate an electric actuator. These advantages claim to help for extraordinary control, endurance, and effectiveness in armored parts as structures with hydraulic controls require tight precision to manage fluid flow.

The marine industry, especially in chemical processing or wastewater treatment plants, requires hefty measures of safeguarding against corrosion. Such industries will deeply appreciate the value of an electric actuator for its ease of automation and remote control, making it ideal for modern automated systems.

Major Attributes of Stainless Steel Electric Flat Gate Valves

Before discussing the advantages, it is important to explain the primary attributes that make stainless steel electric flat gate valves perfect for harsh corrosion applications:

Endurance and Corrosion Endurance

The metallic make-up of stainless steel electric flat gate valves is specifically designed to withstand high amounts of stress is what makes these valves suitable for high corrosion environments. Stainless steel is among the more plentiful alloys as it can be exposed to a wide range of destructive agents like burning, rusting, or acid, and it will not suffer any oxidation. Even in the most demanding conditions, such as saltwater or chemical plant environments, the durability provided by the stainless steel construction ensures a long serving period.

Precise Control with Electric Actuators

Integrated with the valve, the electric actuator enables meticulous control of the opening and closing of valves to ensure flow control is done with finesse. This kind of control is very important in systems where specific flow rates must be sustained like in chemical reactions, water treatment, or even pharmaceutical processes. Remote control is feasible with electric actuators which provides great operational benefits.

Automation and Integration with Control Systems

Electric actuators permit the incorporation of the actuated gate valve into automated systems and thus the valve becomes a manipulated part of the larger control system. Due to this automation, pre-defined operating parameters are set for mechanical valves to function which makes manual oversight less necessary. Electric actuators are ideal for smart technology reliant industries since they can be easily incorporated into SCADA systems and other monitoring systems.

Leak-Proof Sealing

The flat design of the gate in these valves assists improve sealing when the valve is in the closed position. This is particularly critical in areas of high corrosion where leakage might cause contamination, safety issues, or expensive system failures. The leakage sealing capabilities of electric stainless steel flat gate valves improve sealing at brakes and enhance system integrity.

Why Stainless Steel Electric Flat Gate Valves Are Best Fit for High-Corrosion Environments

High corrosion environments bend valves to very peculiar performance specifications, however, actuated gate valves crafted from stainless steel seem to meet these specifics with ease. Below are the primary reasons why they are considered a go-to solution for industries exposed to corrosive substances.

Superior Corrosion Resistance

The stainless steel electric flat gate valve is designed low-maintenance, even in harsh environments. It withstands exposure to acidic chemicals, saline solutions, and high-pressure systems. For oil and gas, marine, and wastewater treatment industries, protective mechanisms from corrosion are crucial to ensure operational continuity and minimize the need for repairs.

Defense From Intense Levels of Heat

In high-corrosion cases, other systems can have the risk of extreme temperatures. Stainless steel’s actuated gate valve is designed to withstand both high and low temperatures, maintaining the strength and structural integrity of stainless steel. Thus making it suitable for processes wherein the temperature of the fluid fluctuates or where the system needs to bear external temperature changes.

Comparison of Compatible Materials

With regards to constructable valve material, certain barriers can prove to be very corrosive. Due to their manufacturing, alloyed chemicals are best suited for industries which deal with caustic substances and reactive chemicals. Thus, tailored to guarantee the valve does not deteriorate under such chemical substances, protecting the system from leaks, contamination and damage.

Less Maintenance And Longer Service Lifetime

Reduction in maintenance is aided by the durability, corrosion resistance of stainless steel. Resulting with a guarantee from the alternate materials being funded towards maintenance for increased picked up arising cost. Proving to be more efficient in money though is dependable with decreased operational downtime and cost with lesser replacements of these valves from used in other non stainless steel valves.

Safety Within Dangerous Work Environments

Areas that are highly corrosive are usually paired with dangerous working environments such as, explosive atmospheres and fluid handling areas. Electric Flat Gate Valves in Stainless Steel are made with safety as a priority. They contain fail-safety functions, effective sealing, and automation that prevents malfunctions and guarantees safe functioning in difficult environments.

Areas Where Electric Flat Gate Valves In Stainless Steel Are Used/Needed

The ability to withstand damages such as corrosion and stress makes stainless steel electric flat gate valves applicable to many areas including to:

Oil and Gas

Valves in the pipelines of oil and gas need to take into consideration the quantitative damage of crude oil, the electric gated valves made out of stainless steel withstand these ailments. For offshore rigs and environments located below sea level, the actuated gates work well for controlling the flow of oil and gas during these critical operations because of their corrosion resistance ensuring performance despite exposure to aggressive substances.

Chemical Processing

The processing of chemicals typically deal with extremely caustic liquids and fumes. The use of stainless steel electric flat gate valves serves to mitigate leakage and prevents the escape of any noxious chemicals which could compromise both human and environmental safety. Their robustness and exactness is crucial for ensuring smooth and safe processes.

Marine Industry

Saltwater is extremely corrosive which makes the marine environment one of the most difficult for industrial machinery. Stainless steel actuated gate valves are ideal for use in ships, offshore platforms and other marine applications. Their resistance to saltwater corrosion and harsh operating conditions is beneficial for these industries.

Water Treatment

Municipal and industrial water treatment plants need valves able to withstand the corrosive nature of chemicals such as chlorine and other aggressive treatment chemicals. Stainless steel electric flat gate valves are strategically advantageous due to the harmful environment of the water and its precise flow control capabilities.

Food and Beverage Sector

In the food and beverage industry, hygiene and safety comes first. The use of stainless steel is a common practice in this industry because it does not react with other metals and is easy to maintain. The actuated gate valve supports proper control of fluids, gases, and other substances in accordance with the food safety requirements of the industry.

How to Choose the Right Steel Electric Flat Gate Valve

Multiple important factors determine the choice of an actuated gate valve in areas of high corrosion.

Material Selection

Due to the presence of highly corrosive materials in certain environments, stainless steel usually becomes the material of choice. But when we talk about stainless steel grades, there are options of 304, 316, or duplex stainless steel which provide some level of protection from corrosion. Selecting the particular grade that corresponds to the conditions that your system will face is important.

Size of the Valves and Their Flows

The size of the valve should correspond to the flow capacity of the pipeline. Valves that do not fit the pipeline size will hinder the performance of the system. Moreover, make sure the valve is appraised for the pressures and temperatures it will face when working.

Electric Actuator Specifications

Electric actuators can be defined by their size, power requirements, and electric torque. Choosing the right actuator for a valve must also include consideration of the force needed for the valve’s operation. In this case, factors such as the speed of opening and closing the valve, precision, and modulating control or on/off control must be considered.

Safety and Environment Considerations

Additional features such as an explosion-proof case, various IP enclosures, or fail-safe constructs are beneficial in strenuous situations. These allow for safe and reliable valve operation in even the most strenuous domains.

Conclusion

The stainless steel electric flat gate valve is one of the best innovations in fluid control technology made for regions with harsh corrosion, as it embodies modern challenges. These valves have integrated automated systems for remote access control, giving them immense operational advantages in fields sensitive to precision, safety and reliability. By deploying the appropriate actuated gate valve, businesses can guarantee seamless operations, lowered maintenance expenditure, and increased lifespan of their systems, which makes the valve invaluable in harsh environmental conditions.

Observer Voice is the one stop site for National, International news, Sports, Editor’s Choice, Art/culture contents, Quotes and much more. We also cover historical contents. Historical contents includes World History, Indian History, and what happened today. The website also covers Entertainment across the India and World.