Breakthrough in Fatigue-Resistant Alloys Unveiled

Researchers at the Indian Institute of Science (IISc) Bangalore have made significant strides in the development of fatigue-resistant multi-principal element alloys (MPEAs). This innovative approach challenges traditional beliefs about alloy composition and fatigue life, potentially transforming their application in various structural contexts. Led by Dr. Ankur Chauhan, the team has systematically investigated microstructural features that enhance the low-cycle fatigue (LCF) performance of these advanced materials.

Understanding Multi-Principle Element Alloys

Multi-principal element alloys (MPEAs) represent a new class of materials that incorporate multiple principal elements, diverging from the conventional use of one or two. Historically, it has been thought that enhancing strength through compositional changes or the introduction of brittle phases could negatively impact fatigue life. However, the research team at IISc has taken a different approach, exploring how specific microstructural characteristics can improve fatigue resistance. This research opens new avenues for the application of MPEAs in demanding environments, where durability and strength are paramount.

Innovative Research Methodology

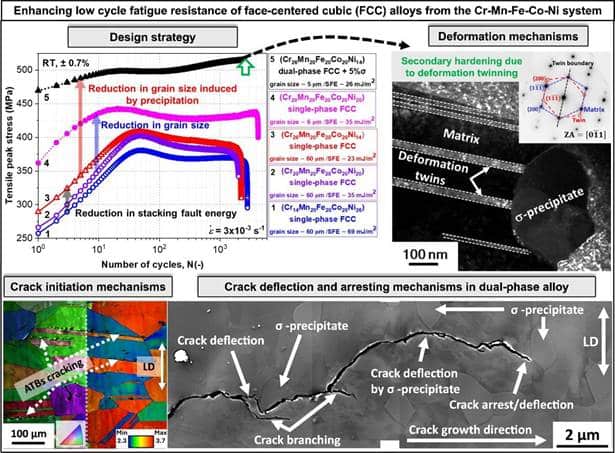

Dr. Chauhan and his team focused on the Cr-Mn-Fe-Co-Ni alloy system, examining the effects of varying the chromium to nickel (Cr/Ni) ratio. They successfully synthesized two distinct single-phase face-centered cubic (FCC) MPEAs, each with unique stacking fault energies (SFEs). The low-SFE alloy demonstrated a remarkable 10–20% increase in cyclic strength compared to its high-SFE counterpart, while both maintained similar fatigue lives. This enhancement in performance is attributed to the delayed formation of dislocation substructures and a reduced rate of crack propagation in the low-SFE alloy, showcasing the potential for tailored alloy designs.

Dual-Phase Alloy Achieves Remarkable Strength

In addition to single-phase alloys, the research team developed a dual-phase alloy that exhibited an impressive 50–65% increase in cyclic strength over the single-phase low-SFE alloy, again without compromising fatigue life. This significant improvement is linked to several factors, including finer dislocation structures, increased back stresses due to smaller grain sizes, and the presence of brittle σ-precipitates that aid in crack deflection. Furthermore, extensive deformation twinning around fatigue cracks complements slip activity, effectively slowing down crack propagation. These findings not only enhance the understanding of MPEAs but also provide a solid framework for future alloy design.

Implications for Future Research and Applications

The insights gained from this research offer a deeper understanding of the mechanisms behind deformation and damage in MPEAs. By elucidating how stacking fault energy and secondary brittle phases influence mechanical properties, this work paves the way for further exploration of complex alloy systems. The research is supported by the Anusandhan National Research Foundation, a statutory body under the Government of India, highlighting the importance of governmental support in advancing materials science. As the demand for stronger, more resilient materials continues to grow, this breakthrough in fatigue-resistant alloys could have far-reaching implications across various industries.

Observer Voice is the one stop site for National, International news, Sports, Editor’s Choice, Art/culture contents, Quotes and much more. We also cover historical contents. Historical contents includes World History, Indian History, and what happened today. The website also covers Entertainment across the India and World.